The Marsh 241D thermal printhead and control software has been optimised to work with the Marsh ActiveCore™ ribbon to provide high print quality and strong adhesion to most flexible packaging and label substrates.

Print adhesion is subjective all over the world with different industries and customers requiring different standards of adhesion depending on the product they are producing.

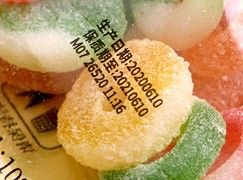

3 common factors impact how well the printed image sticks to the substrate:

- Heat – How hot the printhead dot heats the ink when the image is transferred to the packaging material.

- Time – How long the printed image is left for heat to dissipate before being touched.

- Material – The biggest variable is packaging materials with some better/worse at allowing ink to adhere to them.

To ensure the Marsh 241D print adhesion is the best possible, please follow the points below:

- Installation and set-up: Ensure the Marsh 241D coder has been installed using the gap setting tool. For optimal print adhesion and print quality, the Marsh 241D platen gap should be set between 2.00mm and 2.20mm. This is reported and can be checked using the Marsh 241D mobile app (Coder Control > Settings > My Coder).

For details on Marsh 241D Installation, just Sign In (or Register first, if you haven't already) and then refer to the M241D Installation Guide in the Document Library.

- Time: To ensure the printed image has fully adhered to the packaging material, all heat must be removed from the ink and packaging material. This time allows the chemicals in the ink to solidify and adhere to the material. Depending on operating conditions, substrate thickness and chemical composition of the packaging material, this process of adhesion can take between 5 minutes and 24 hours.

Testing print adhesion straight after it has been printed will result in an invalid test of the Marsh 241D print adhesion as the ink has not had a chance to cool adhere to the material.

- Heat: Print adhesion can also be improved by increasing the print heat of the Marsh 241D coder (Print heat is also referred to as print darkness in some documentation).

Please refer to “How do I make my print darker?” in the knowledge base for more information.

Note: Increasing print heat makes the printed image appear darker but also increases the time required for the chemicals in the ink to cool, solidify and adhere to the material. This must be considered when testing print adhesion.