The M241D coder has an adjustable parameter to add a time delay from when the M241D coder receives an external print trigger to when the M241D starts printing. Please see the ‘What is the print delay’ article to understand what print delay is and how it can be adjusted using the M241D mobile app.

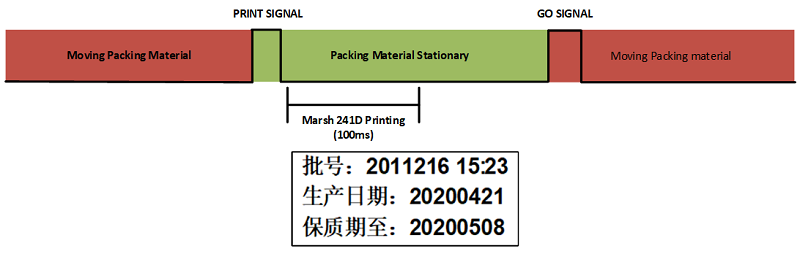

Intermittent printing is used on lines where the web transport moves in an intermittent motion (stop/start). The stop-time (dwell time) within the cycle is used for printing.

During this dwell-time and using a signal from the packaging machine, the M241D lowers the printhead and moves across the printing surface. When the print is complete, the film is released and the printhead returns to its start position.

In a perfect installation, when the host packaging machine sends the print single to the M241D when the packaging material is perfectly stationary.

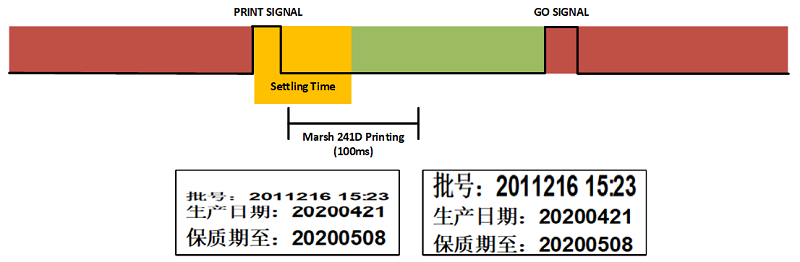

However, most packaging machines send the print signal at the same time as the packaging material sends stops moving the packaging material. Due to manufacturing tolerances, material type, material width, system lag and many other variables, the packaging material does not stop instantly and takes time to settle.

As stated previously, to get the best print quality from the M241D – the packaging material must be perfectly still when the printhead is contacting the packaging material during the printing process. If the material is still moving during the start of the print, you might encounter stretched or compressed prints. Examples below.

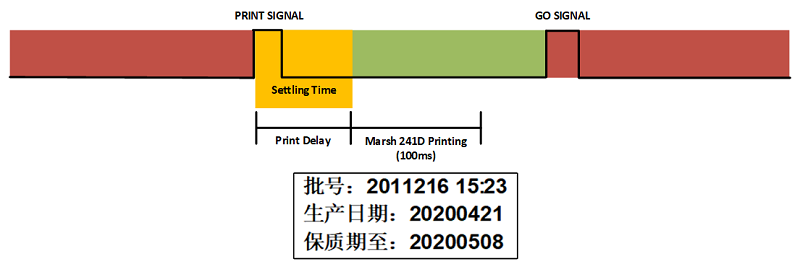

The M241D coder has an adjustable parameter called ‘print delay’ to add a time delay from when the M241D coder receives an external print trigger to when the M241D starts printing. This allows the host machine more time for the packaging material to settle and ensure it is perfectly still when the M241D is printing. The print delay of the M241D can be changed using the M241D App. The maximum print delay is 500ms. Example below.

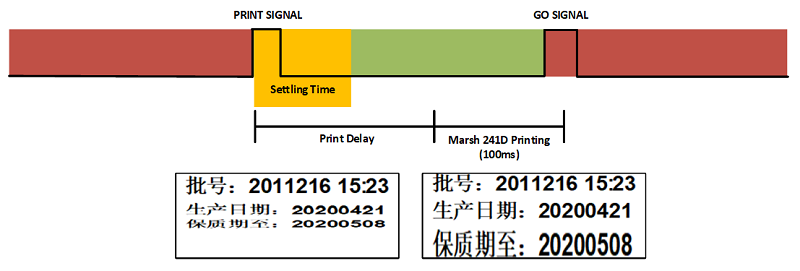

Adding too much print delay can cause the M241D to still be printing when the host packaging starts moving the packaging material again. If the material starts moving during the print, you might encounter stretched or compressed prints at the end of the print. Examples below.

Best practice when using print delay:

- Before connecting the M241D to the host packaging machine and running together (during the dwell time). Install the M241D in the host packaging machine and complete a manual test print (IO cable not connected). See ‘How to issue a manual test print on an M241D coder’ for more information.

o This takes out any variation due to the host packaging machine and gives an example print to compare against.

- If adding at a print delay – Start at 0 and add in 50ms increments.

o The aim is to add the smallest delay to give you the print consistent print quality throughout the roll.

- Once you have added a print delay - Check the print quality throughout a complete roll of packaging material

o As rolls of packaging material decrease, the mass and movement can vary compared to the start of a new roll.

o You might need to add a little (less than 50ms) more delay to give you the best print quality throughout the roll and prevent the need to adjust each roll.