Food Safety Law strictly regulates information, such as production date and product shelf life printed on pre-packaged food – when there is an error or inaccuracy in the information provided, the corresponding product(s) must be withdrawn and recalled if sold to final consumers. Conducting a product withdrawal/recall is costly. It also tarnishes the brand reputation and causes customers to lose confidence and trust in the product(s) or brand. The lost customer confidence and trust take plenty of time and extensive marketing to restore. But what could be the hidden costs of product coding errors? How does a manufacturer avoid these errors?

Human error costs time and money

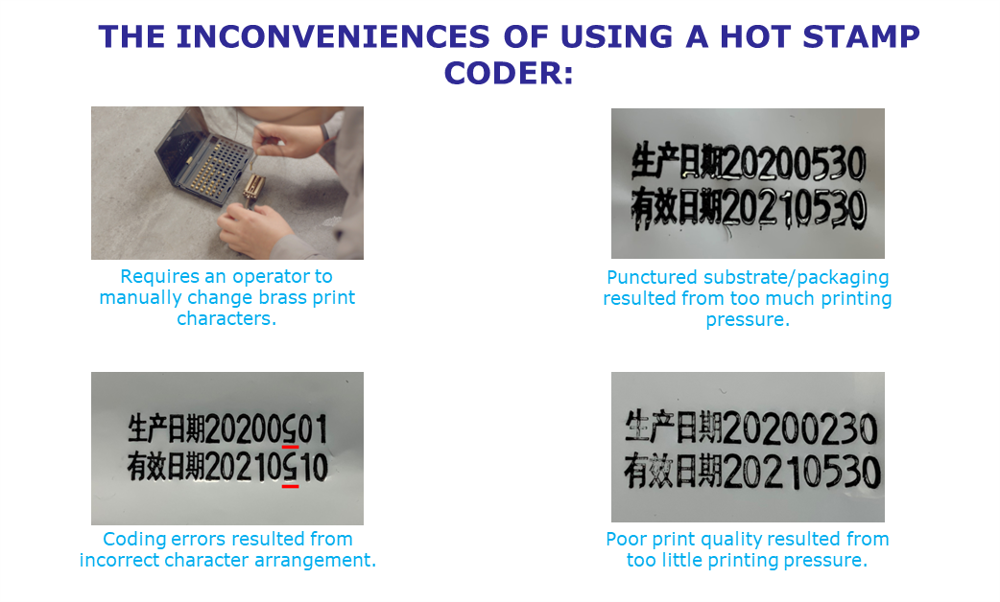

A simple human error, such as an operator inserting the wrong brass characters or print block into a hot stamp coder, creates hidden operating costs. Operators who used hot stamp coders before would know how easy it is to transpose or reverse characters when inserting characters manually. For example, a product that should have Monday ‘01’ (January) on the packaging has a month of ‘10’ due to the incorrect arrangement of print characters, causing the best before to be wrong by 9 months – losing product traceability, which adds significant risk to food quality, and food safety.

Manufacturers will have periodic production checks or pre-shipment checks to detect this error and prevent a full-scale product recall or withdrawal. But by that point, there may already have been many hour-worth of incorrect codes printed on products – the operation did not help prevent the hidden costs: wasted product and packaging, stock write-off (including storage, logistics and disposal costs), etc.

Coding errors result in lost sales

In an efficient just-in-time manufacturing scenario, or for short shelf-life items, finding product coding errors during checks could also lead to an inability to meet deadlines as the product is re-packaged, resulting in lost revenue and profits.

Precise packaging codes are a legal requirement

A date code is just one small part of a finished product but is a legal requirement. Incorrect or inaccurate date codes may cause manufacturers to receive regulatory penalties and fines. Thus, it is best to have different people check the printed dates frequently and ensure the setup is accurate, preventing hot stamp coders from punching the wrong date for several hours before identifying the issue. BRC Food Safety standard – one of the most recognised Global Standards – encourages manufacturers to run checks at the start of each production, at the end of it and every twenty minutes during the process to ensure no issues.

Digital hot stamp coders help reduce costs

It is best to adopt digital printing technology that automatically updates dates when printing codes, eliminating human error and avoiding coding errors. However, advanced printers like industrial continuous inkjet printers (CIJ) and thermal transfer overprinters (TTO) may be beyond the budgets of small and medium-sized enterprises. The good news is the self-sufficient Marsh 241D digital hot stamp coders are available now! Marsh 241D coders allow users to edit codes through the M241D app and print automatic dates, fixed dates, and offset dates, eliminating human error and removing all hidden costs of coding errors. The best part is every real-time code Marsh 241D coders print is the same price as every fixed code hot stamp coders punch!

For more information, please visit marshcoding.com!